The metal coil is flattened by a combined “straightening-flattening” system, with edge trimming to eliminate the oxidized and / or deformed parts, cut in length by a “slitter” and diagonally by a “roller cutters”.

Conical poles from sheet metal to octagonal section with double squared arm PNI 8800/3

Description

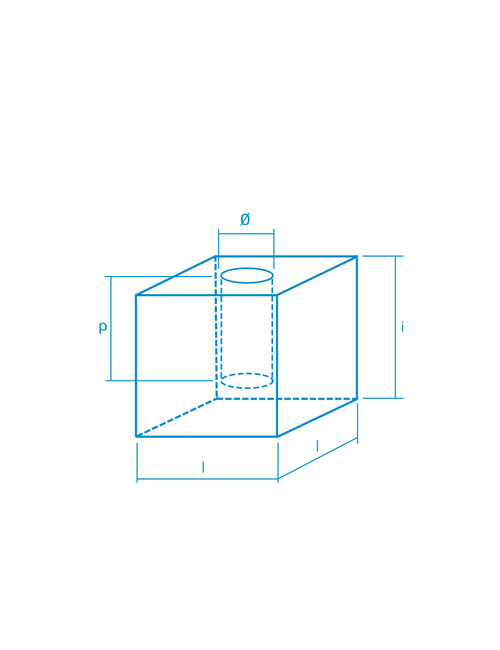

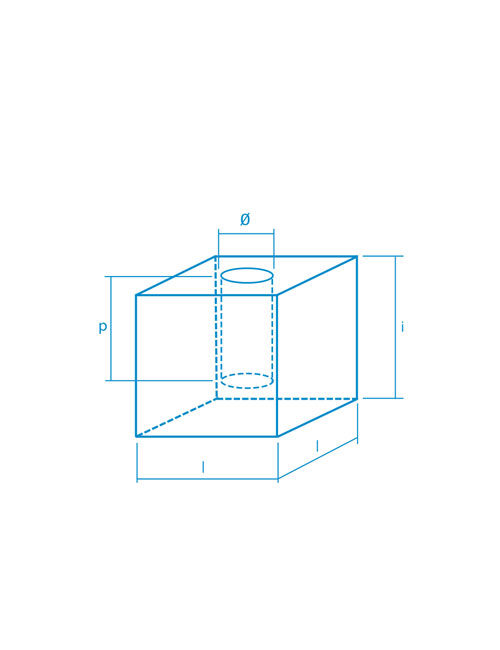

| L mm | H mm | D mm | d mm | P Kg | S m2 | Ø mm | i mm | I mm | p mm |

|---|---|---|---|---|---|---|---|---|---|

| 8800 | 8000 | 151 | 60 | 69 | 2,9 | 300 | 1000 | 950 | 800 |

FLOW TABLE

Maximum surface exposed to the wind depending on the area and the exposure category (m2)

| codice | w mm | h1D mm | d mm | sp | P Kg | α° | descrizione | Cod |

|---|---|---|---|---|---|---|---|---|

| PDI 1000 | 1000 | 350 | 60 | 3 | 10 | 0 | double squared arm type 1 | d1 |

| PDI 1500 | 1500 | 500 | 60 | 3 | 15 | 0 | double squared arm type 2 | d2 |

| PDI 2000 | 2000 | 600 | 60 | 3 | 20 | 0 | double squared arm type 3 | d3 |

| zona 1 (max 1000 m s.l.m.) zona 2 (max 750 m s.l.m.) Vref0 25 m/s |

zona 3 (max 500 m s.l.m.) Vref0 27 m/s |

zona 4-6 (max 500 m s.l.m.) zona 5 (max 750 m s.l.m.) Vref0 28 m/s |

zona 7 (max 1000 m s.l.m.) Vref0 29 m/s |

zona 8 (max 1500 m s.l.m.) zona 9 (max 500 m s.l.m.) Vref0 31 m/s |

|||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| – | – | d1 | d2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Cut into conical shape

The trapezoid is formed into a cone shape using a bending press equipped by automatic manipulators which are numerically controlled.

Welding

The edges of the truncated cone are joined longitudinally by automatic and manual welding procedures. The welding is carried out in compliance with specific processing techniques (WPS) compliant with the UNI EN standards ISO 15609-2 and adopting qualified procedures (WPAR) in compliance with UNI EN ISO 15614-1 standards. All the welding employees are qualified according to UNI EN 1418 and 287-1 standards and are supported and controlled by supervision with international qualifications (International Welding Engineer). In this regard, welding is subject to visual inspection (VT) performed by qualified personnel in compliance with the UNI EN 473 standard.

Tolerances

The machining tolerances comply with the UNI EN 40-2 standard.

Finishing

Once the lamination phase is completed, the pole is subjected to specific operations at the base (i.e. slots) and at the tip (i.e. calibration).

Galvanizing

The internal and external surface protection is guaranteed by a hot galvanizing process carried out from its immersion in a bath of molten zinc, after pickling aimed at eliminating any slag and impurities. The galvanizing process is manufactured in compliance with the UNI EN ISO 1461 standard or, upon request, in compliance with the CEI 7-6 standard dossier n. 239.

For aesthetic reasons aimed at favoring the insertion of the pole within the urban context or for the need to strengthen the protection against corrosion, the pole, on request, can be painted.

Materials

The poles are made using steel sheet S235JR (Fe 360B) with mechanical characteristics that comply with the UNI EN 10025 standard.

Testing

Each processing phase is subject to constant monitoring by employees who work under the supervision of the department head, who reports directly to the Quality Control Office.

Additional information

| Categoria di terreno | I – Sea coast, II – Cultivated land, III – Suburban areas, IV – Urban areas |

|---|---|

| Numero di apparecchi | 2 |

| Altezza punto luce | 8000 |