The HSP pole is obtained by hot rolling S275JR UNI EN 10025 steel pipe, welded at high frequency ERW ( Electrical resistance welded ) according to the UNI 7091/72 standards.The pipe is laminated at a temperature of 700°C; the process, entirely managed by numerical control, is aimed at increasing the mechanical characteristics of the steel.

Hot rolled HSP poles with double squared arm pcs 0040

Description

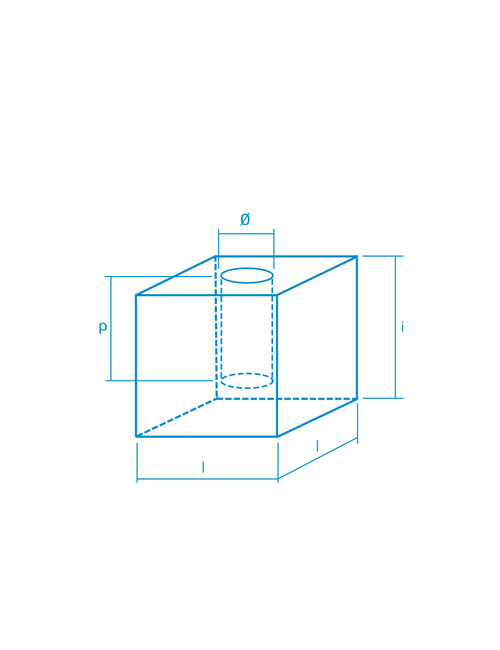

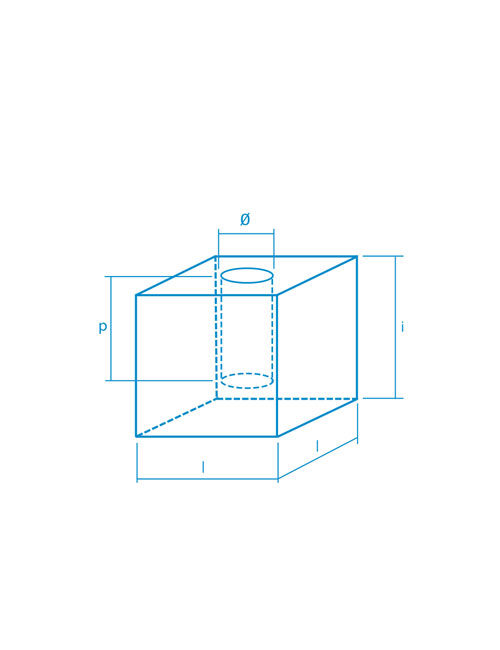

| L mm | H mm | D mm | d mm | sp mm | P Kg | S m2 | Ø mm | i mm | I mm | p mm |

|---|---|---|---|---|---|---|---|---|---|---|

| 7800 | 7000 | 127,0 | 65 | 3,6 | 78 | 2,45 | 300 | 1000 | 950 | 800 |

FLOW TABLE

Maximum surface exposed to the wind depending on the area and the exposure category (m2)

| codice | w mm | h1D mm | d mm | sp | P Kg | α° | descrizione | Cod |

|---|---|---|---|---|---|---|---|---|

| PDI 1000 | 1000 | 350 | 60 | 3 | 10 | 0 | double squared arm type 1 | d1 |

| PDI 1500 | 1500 | 500 | 60 | 3 | 15 | 0 | double squared arm type 2 | d2 |

| PDI 2000 | 2000 | 600 | 60 | 3 | 20 | 0 | double squared arm type 3 | d3 |

| zona 1 (max 1000 m s.l.m.) zona 2 (max 750 m s.l.m.) Vref0 25 m/s |

zona 3 (max 500 m s.l.m.) Vref0 27 m/s |

zona 4-6 (max 500 m s.l.m.) zona 5 (max 750 m s.l.m.) Vref0 28 m/s |

zona 7 (max 1000 m s.l.m.) Vref0 29 m/s |

zona 8 (max 1500 m s.l.m.) zona 9 (max 500 m s.l.m.) Vref0 31 m/s |

|||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I | II | III | IV | I | II | III | IV | I | II | III | IV | I | II | III | IV | I | II | III | IV |

| d3 | d3 | d3 | d3 | d2 | d3 | d3 | d3 | d2 | d3 | d3 | d3 | d1 | d3 | d3 | d3 | – | d1 | d3 | d3 |

Outer Surface

The lamination process makes it possible to obtain a highly appealing product as it is free of external welding; the surface of the pole appears to be perfectly uniform.

Performance

The steel used and the increase in thickness due to hot lamination, (from the base to the top of the pipe) confers to the pole a superior performance. In the presence of strong winds, the oscillations are therefore reduced to a minimum with considerable benefits for the duration of the lighting body and the effect of transmitting a tangible “sense of safety and stability”.

Tolerances

The machining tolerances comply with the UNI EN 40-2 standard.

Finishing

Once the lamination phase is completed, the pole is subjected to specific operations at the base (i.e. slots) and at the tip (i.e. calibration).

Galvanizing

The internal and external surface protection is guaranteed by a hot galvanizing process carried out from its immersion in a bath of molten zinc, after pickling aimed at eliminating any slag and impurities. The galvanizing process is manufactured in compliance with the UNI EN ISO 1461 standard or, upon request, in compliance with the CEI 7-6 standard dossier n. 239. For aesthetic reasons aimed at favoring the insertion of the pole within the urban context or for the need to strengthen the protection against corrosion, the pole, on request, can be painted.

Materials

The poles are made using standard S275JR steel pipes (Fe 430B) with mechanical characteristics that comply with the UNI EN 10025 standard.

Testing

§Each processing phase is subject to constant monitoring by employees who work under the supervision of the department head, who reports directly to the Quality Control Office.

Additional information

| Categoria di terreno | I – Sea coast, II – Cultivated land, III – Suburban areas, IV – Urban areas |

|---|---|

| Numero di apparecchi | 2 |

| Altezza punto luce | 7000 |

| Zona vento | AREA 1, AREA 2, AREA 3, AREA 4, AREA 5, AREA 6, AREA 7 |